LNG Transfer Training – 3D Visualisation Application

Project Overview:

For this project we were approached by GTT Training, a specialist LNG (Liquified Natural Gas) management training company, with a requirement to develop a 3D visualisation application that would integrate with their “G-Sim” product. “G-Sim” is a Liquid Gas Handling Simulator, which realistically replicates the operational system used to manage the movement of LNG around a cargo vessel. One element that “G-Sim” was missing was the ability for the operators to see, through a simulated CCTV feed, the bunkering room where the transfer of LNG from an external source to the cargo vessel takes place. This is something that operators have access to in the real-world and so GTT Training were keen to enable their clients to experience this using “G-Sim”.

Project Features:

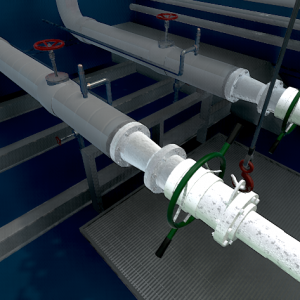

The 3D visualisation application we developed for GTT Training provides the user with a realistic graphical representation of a typical LNG cargo vessel bunkering room and pipe configuration within it. Functionally, the 3D visualisation application is fully integrated with “G-Sim” so that the actions taken by a user of “G-Sim” are accurately reflected and visualised through the application running alongside “G-Sim”.

The 3D visualisation application visualises the following actions which are all caused by the user of “G-Sim”:

- Connecting and disconnecting of pipes.

- Effects of pipe frosting during LNG transfer.

- Effects of pipe leakages when there is a fault.

- “White-out” effects caused by incorrect connection of pipes.

The application also visually reflects the ability of the “G-Sim” user to speed up and slow down the simulator time.

Solution Benefits:

- The 3D visualisation we developed for GTT Training enables them to offer their clients an added level of realism of their “G-Sim” product which in turn will help them provide even greater training value.

- It helps trainees to see there progress as they move through the procedure and identify when they have done something wrong.

Interactive Maintenance Trainer – Virtual Training Application

Project Overview:

We know that “practice by doing” is the best form of training but, access to training equipment can often be limited. We develop virtual, interactive training solutions to help make technical training on large and/or complex equipment more accessible, more effective and more relevant to the workforce of today. The Agility3 Interactive Maintenance Trainer (IMT) demonstrator is an example of this and provides an insight into the type of solutions that are possible.

Project Features:

The virtual, interactive training solutions we develop are built to our clients specifications and fully customisable in terms of the virtual content, interactivity, functionality and delivery platform.

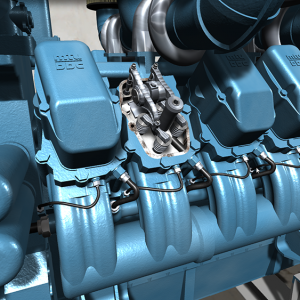

The IMT provides an example of the features that can be built in. Whether it is being run on a laptop, mobile device or large touchscreen, the user is presented with a virtual representation of a diesel generator situated within a virtual room environment. The user can navigate around the equipment and interact with it. When the diesel generator is turned on the equipment vibrates into life as it would in the real-world. The demonstrator has two separate faults built-in which inhibit the normal operating behaviour. By interacting with the equipment and removing, inspecting and replacing various parts, users can carry out the procedure to identify, diagnose and fix those faults and return the equipment back to its normal behaviour.

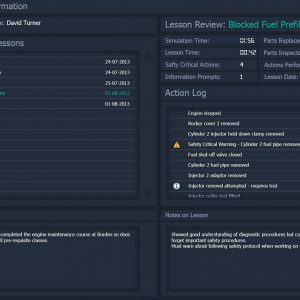

Although not fully functional within the demonstrator, the IMT also shows how users the user can bring up technical publications to support training and understanding as well as showing how action tracking and instructor lesson management tools can be implemented.

Solution Benefits:

- The IMT is an example of how virtual, interactive training solutions can enhance learning, support knowledge retention, reduce skill fade and provide multiple benefits for trainee and trainer.

- Trainees can have constant access to a highly realistic representation of the training equipment which they can practice on whenever needed.

- Trainees can carry out procedures in the safety of the virtual environment where mistakes can be made with no risk of injury or equipment breakage.

- Training costs can be reduced by not needing trainees to travel to specific locations for training.

- These solutions provide high training value which is the next best thing to hands-on practical training, which is also fun and enjoyable.

- Through instructor monitoring tools, trainers can closely manage and monitor the lessons that trainees are going through and get effective feedback on performance.

WindTwin – 3D Visualisation Application

Project Overview:

“WindTwin” was a 30-month project funded by Innovate UK. The aims of the project were to develop an innovative solution for the preventive and predictive maintenance of wind turbines based on a combined data and physics-based hybrid twin solution. We worked on the project with a consortium of project partners including Brunel University London, Dashboard Ltd, ESI Group, and TWI Ltd.

Project Features:

Our contribution to the project was in the development of an interactive 3D application that enabled the effective and easy visualisation of sensor data received from real wind turbine assets.

This application is called “Twin3D” and it has the following features:

- It is a cloud hosted application launched through a web browser.

- An easy to use, intuitive User Interface allowing users to jump to individual turbines and internal systems.

- The ability for the user to select any date and time, past, present or future, and visualise the status/predicted status of the wind turbines at that moment.

- Makes potential system faults and issues easy to identify by highlighting them with different warning levels.

Solution Benefits:

Being able to easily visualise and identify potential fault and issues, this type of solution would enable wind farm operators to improve planning and optimise the maintenance activities to take place on the real wind turbine assets resulting in potentially significant time and cost savings.