A little while back, in 2022, Agility3 supplied a proof of concept to Transport for London (TfL) in response to their idea to virtually design a control room and immerse users in it, to provide better informed feedback earlier and continuously throughout the design process.

And now, we’re delighted to announce that this proof of concept was successful, and that, as a result, TfL has commissioned us to build the full application in a project that kicked off in February and is expected to run for around 12 months.

What will the project deliver?

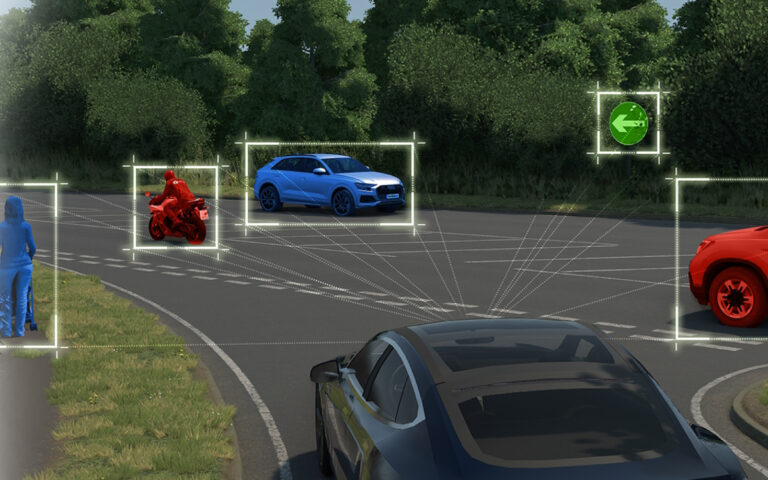

As with many of the 3D visualisation projects that we undertake for our customers in the rail sector, the goal of this TfL project is ultimately to use virtual methods to reduce capital and operations cost and mitigate risk.

Designing and testing in the virtual world can highlight issues early and more efficiently than could be done using more traditional methods, reducing the cost associated with system development.

The project combines virtual reality and simulation technology to provide an immersive and interactive virtual environment, in which TfL experts in human factors and project stakeholders alike can experience a proposed control room design and interact realistically with the equipment within it according to TfL operating processes. As part of system performance assessments, design changes can be quickly made to any of these interacting components and performance reassessed until it is optimised. This is the key idea at the heart of TfL’s ‘Virtual Control Room’ vision.

This revolutionises the design process by helping to inform decisions about, amongst others, control room layout and equipment configuration, without the need to build physical prototypes.

How will the application work?

As with the proof of concept before it, the unique value of this application will be its ability to visually and functionally integrate three sources of data:

- Control Room Design. The application provides tools enabling users to build a digital twin of a proposed Control Room. Users can then immerse themselves in the virtual room and experience the room using immersive virtual reality, delivered through headsets.

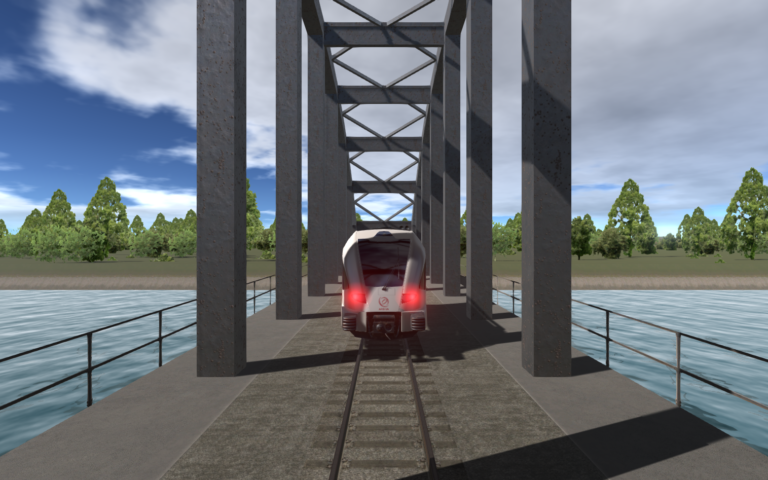

- TfL’s powerful Railway Engineering Simulator, which accurately simulates an entire railway line.

- Real Operational software, used by TfL in everyday operations.

This combination means the user will be immersed in a virtual control room exactly like the proposed room, and they will see realistic data and applications on their screens, exactly as they would in a real control room, but generated from the simulation.

But it also means that when they look around, they will see the room itself, including other screens, displays, equipment and even other team members. And when they look down, they will be able to see their real keyboard and mouse and use them to interact with the applications within the virtual environment.

Human response, operational improvement

At the same time, because the application will enable real human operators to work as if they were in a physical control room, it will make it possible to trial and maintain the levels of collaboration and performance of control room teams (including trainees) in the sort of high-pressure scenarios they are likely to experience ‘on the job’; and again, done in a more efficient way compared to more traditional methods.

The application will then also provide a representative platform for the testing and evaluation of enhancements and upgrades, before they leave the design table.

For rail and beyond

Although the TfL application will be built specifically for TfL’s rail context, just like the proof of concept that preceded it, the reality is that any industry that requires an operational environment can potentially benefit from a virtual solution of this kind.

If that sounds like your industry, we should start a conversation.

For more information on our 3D visualisation, modelling, and simulation solutions for rail, road, driving, and other sectors, get in touch.